Batch sizes on the increase and you want to fit more parts in your vertical miller?

Already invested in vertical milling machines but your needs have changed?

Wish you had a horizontal miller but don’t have the space?

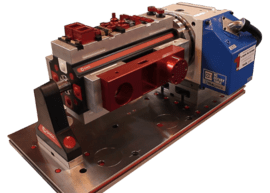

If you want to improve the productivity of your vertical milling machine, the Chick Workholding Indexer SubSystem may be the ideal solution for you.

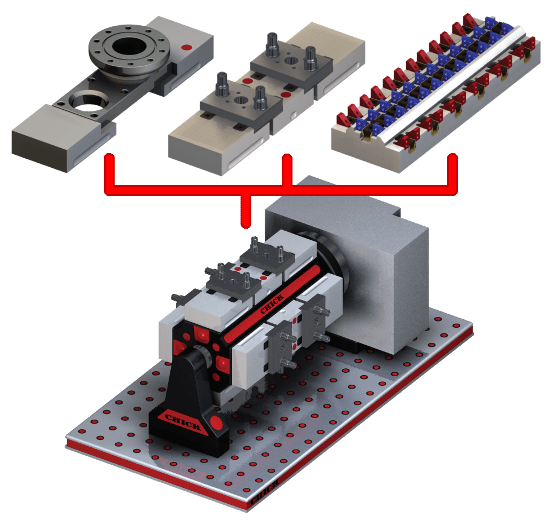

Essentially, the ISS is a workholding system that mounts to a rotary table and provides four or six sides on which to mount your workpieces.

Similar to a tombstone, the ISS has multiple faces for mounting workpieces and is indexed to present the workpieces to the spindle in multiple orientations, but unlike a tombstone it is supported at both ends.

This innovative solution allows the milling spindle to approach the workpiece in the same orientation as in a horizontal miller, but in a vertical miller.

The ISS can be supplied as a package with a 4th axis rotary table, or fitted to your existing setup.

It uses the same trusted quick change system as the rest of the Chick System 5 range and accepts single or dual station jaw sets for one or two workpieces per side, and the built-in zero point system means it’s easy to replace the jaws with machinable faceplates for large quantities of small components.

The machinable jaws create a versatile system that can easily cope with complex shaped workpieces like castings and there is a variety of jaws and faceplates available to accommodate your biggest and your smallest workpieces.

The ISS allows you to fit more workpieces in your machine, in more orientations, and makes it possible to complete machining operations on six sides of your components in a single machining cycle.

It also allows you to reduce your setup time and provides an easy solution for complex component clamping without the need for expensive fixtures.

These benefits result in:

If you are interested in investigating the ISS further, please contact 1st MTA on 01725 512517 or enquiries@1mta.com for a FREE on-site visit from one of our technical engineers who will be happy to discuss the ISS and its benefits in more detail.