Following on from our previous previews of 1st MTA’s presence at the 2016 Mach Exhibition, here you can see a sample of the Iemca barfeeders, and Darex Drill Sharpeners we will be exhibiting. If you would like to see our previous Mach 2016 previews, please follow the links below.

Mach 2016 Preview – Tecnomagnete

Mach 2016 Preview – Chick Workholding and Kitagawa NC Rotary Tables

Mach 2016 Preview – Collet Chucks, Bespoke Chuck Jaws, and Steady Rests

BAR FEEDING

The Italian-built Iemca range of shop floor automation equipment will be represented on the stand by two automatic bar magazines for lathes. The Iemca KID 80 features outstanding versatility, as it is suitable for fixed- and sliding-headstock single-spindle turning machines, either CNC or cam-type. It can accommodate bar diameters from 5 to 80 mm and lengths up to 1,615 mm and can also handle bar pieces by inserting them into the spindle.

The ideal application for the compact feeder is in a production environment producing small to medium sized batch quantities with frequent work setups. Changeover from one bar diameter to another is performed rapidly and easily. The system is entirely mechanical, assuring reliable performance and efficiency. No compressed air connections are required.

The Iemca Boss 21 bar magazine for use with both sliding-head and fixed-head lathes will also make an appearance. It is a compact model for feeding bar from 5 to 51 mm in diameter and with a maximum length of just over two metres, making it a good choice if a long bar feeder is required but space is restricted. Less material is lost through remnants than if shorter bar is used and longer periods of unattended running are possible.

The Iemca Master 80 UP HyperFlexible bar magazine for feeding stock from 15 to 80 mm diameter will also be promoted. It has a novel loading system that allows bars to be presented ergonomically at a height without the operator having to bend the back or arms or lean into the rack. Stock can be transported to the loading position by fork lift truck, hand pallet truck, overhead crane, a hoist or a handling trolley. The bars then enter the magazine via an inclined chute and are raised one by one to rack level automatically by a fully guarded, integral, vertical lift system.

Flexibility for users that set up jobs frequently across a wide range of bar diameters, without the inconvenience of spending much time changing the guide channel each time, is the principal advantage of the magazine’s design. It means that changeover from one bar to the next can be accomplished in around one minute, leading to minimal lathe idle time. Only the pusher collet and the two-part front bushing need to be exchanged. On other bar feeders, from three to six different sizes of channel would be needed to span a bar diameter range of 15 to 80 mm.

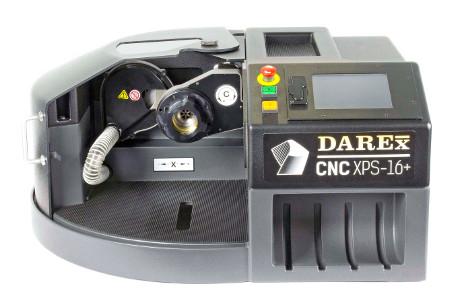

4-AXIS CNC DRILL SHARPENER

Darex, the US manufacturer of drill sharpening equipment represented in the UK exclusively by 1st MTA, has introduced a new, automatic, 4-axis CNC machine that is a faster and more accurate than its predecessor. A collet chuck version of the bench-top machine will be demonstrated for the first time at MACH.

Designated XPS-16+, it can process two-fluted high-speed-steel, cobalt, carbide and coated bits from 3 to 16 mm in diameter and can create any point angle from 90 degrees to 150 degrees as standard. The unit also sharpens split point geometries and complex, 4-facet point drills and can automatically hone carbide drills for high cutting precision. The CNC system allows the user to customise point styles and save the program for future use.

Further improvements over the previous model include an increased number of stored drill files; users can save up to 100 geometries. The upgraded machine also allows the user to choose between no-split, X-split, R-split and the new split-only option. The start of the grind position has been incremented, resulting in more efficient use of the abrasive for longer wheel life. In addition, greater resolution has been added to the motors for improved surface finish

1st Machine Tool Accessories will be exhibiting during the Mach Exhibition in Hall 5 Stand 5120 where you will be able to see the Iemca barfeeders, along with the Darex Drill Sharpeners in action.

If you have questions about these, or any other products we supply, please don’t hesitate to contact us on 01725 512 517 or enquiries@1mta.com.