How Automation, AI, and Workholding Innovation Are Reshaping Industry, Skills and Careers in the UK Executive Summary With investment in automation in UK factories predicted to grow steeply over the next five years, the real challenge is not the availability of the technology, but its practical adoption. OEMs and subcontractors widely report that a lack […]

Read more

Offering unparalleled freedom to produce complex components in a limited number of setups, frequently one, 5-axis prismatic machining delivers high accuracy parts by minimising tolerance build-up and virtually eliminates scrap by removing the risk of manual handling errors. Yet the significant investment required to purchase such high-technology machine tools is often undermined by insufficient attention […]

Read more

At 1st MTA, we understand that maintaining your workholding systems is key to keeping your machines running reliably, accurately, and safely. Proper maintenance of Kitagawa power chucks and hydraulic cylinders not only prolongs their lifespan but also ensures consistent performance and prevents costly downtime. This guide outlines recommended daily, monthly, and semi-annual maintenance tasks, along […]

Read more

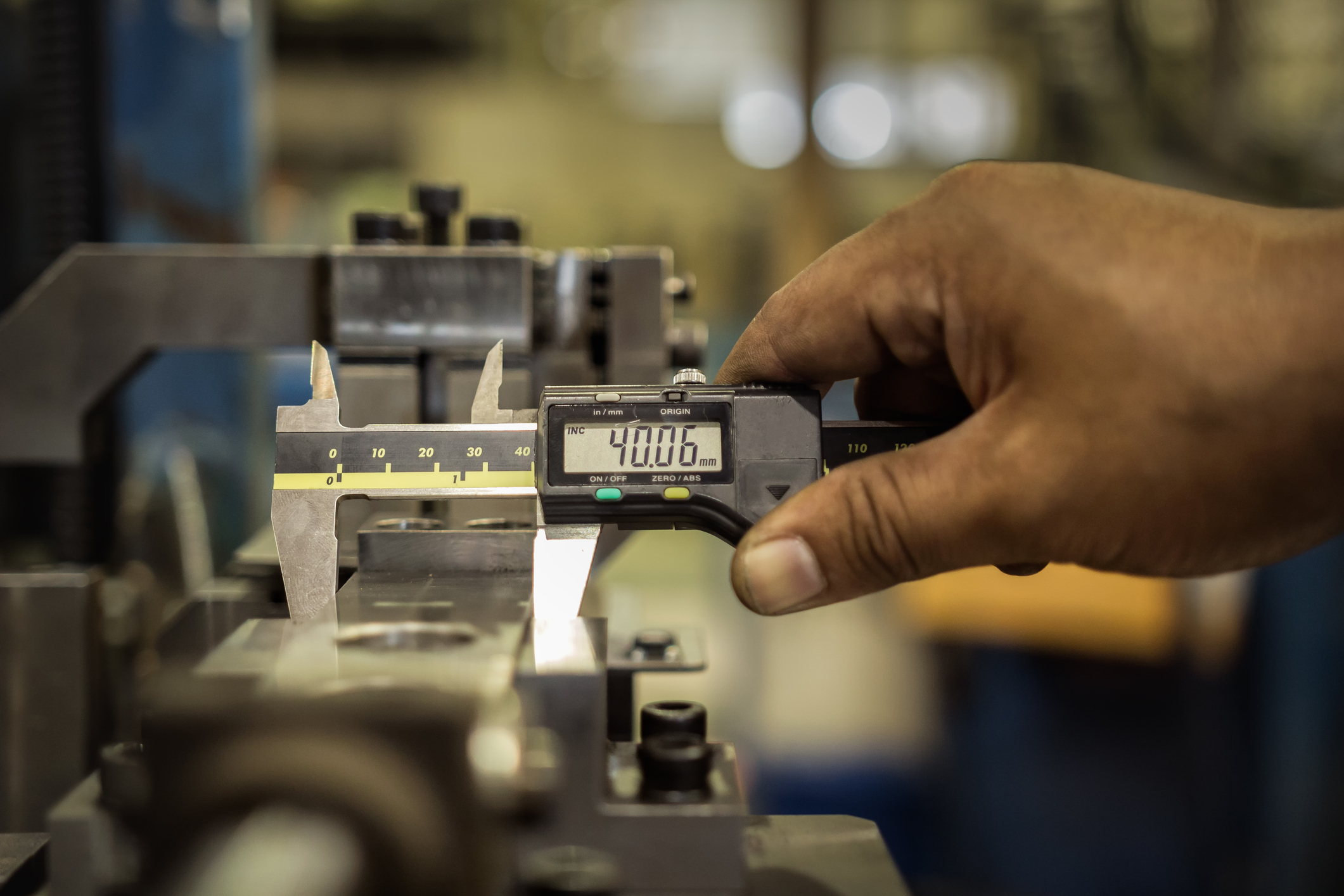

Workholding may not always be the most glamorous part of machining, but it is one of the most important. For engineers, a strong understanding of workholding principles is essential—it directly influences product quality, efficiency, safety, and overall manufacturing costs. The Importance of Workholding Knowledge At its core, workholding ensures that a workpiece is positioned securely […]

Read more

The UK manufacturing sector has long been a cornerstone of the economy, driving innovation, exports, and high-value employment. Yet, it faces a critical and growing challenge: the skills gap. Across the industry, manufacturers are struggling to recruit and retain the skilled people they need to grow, innovate, and remain competitive. The scale of the […]

Read more

In the world of CNC machining, the spotlight is often on precision equipment, advanced automation, and cutting-edge control systems. But when it comes to solving real-world workholding challenges, the technology itself is only part of the equation. The often-overlooked variable — and arguably the most critical — is people. Workholding may appear to be a […]

Read more

Walmag – Smart & Safe Magnetic Workholding Solutions At 1st MTA, we are always seeking to bring innovative and reliable workholding technologies to our customers. That’s why we’re proud to partner with Walmag, a leading name in magnetic workholding solutions. With over 25 years of experience and manufacturing expertise based in the Czech Republic, Walmag […]

Read more

Magnetics – The Future of Workholding For decades, magnetic workholding was considered a niche solution—ideal for flat plate materials on surface grinders, but rarely trusted beyond that. Today, however, the landscape of modern machining is changing rapidly. Thanks to major advancements in magnetic technology, magnets are now proving to be a powerful and flexible solution […]

Read more

Get a Grip: Why Expanding Mandrels from 1st MTA Are the Smart Choice for Internal Workholding When it comes to workholding, external clamping gets most of the attention — but internal gripping is often the real challenge. Whether you’re working with thin-walled parts, precision bores, or long, awkward components, choosing the right mandrel can make […]

Read more

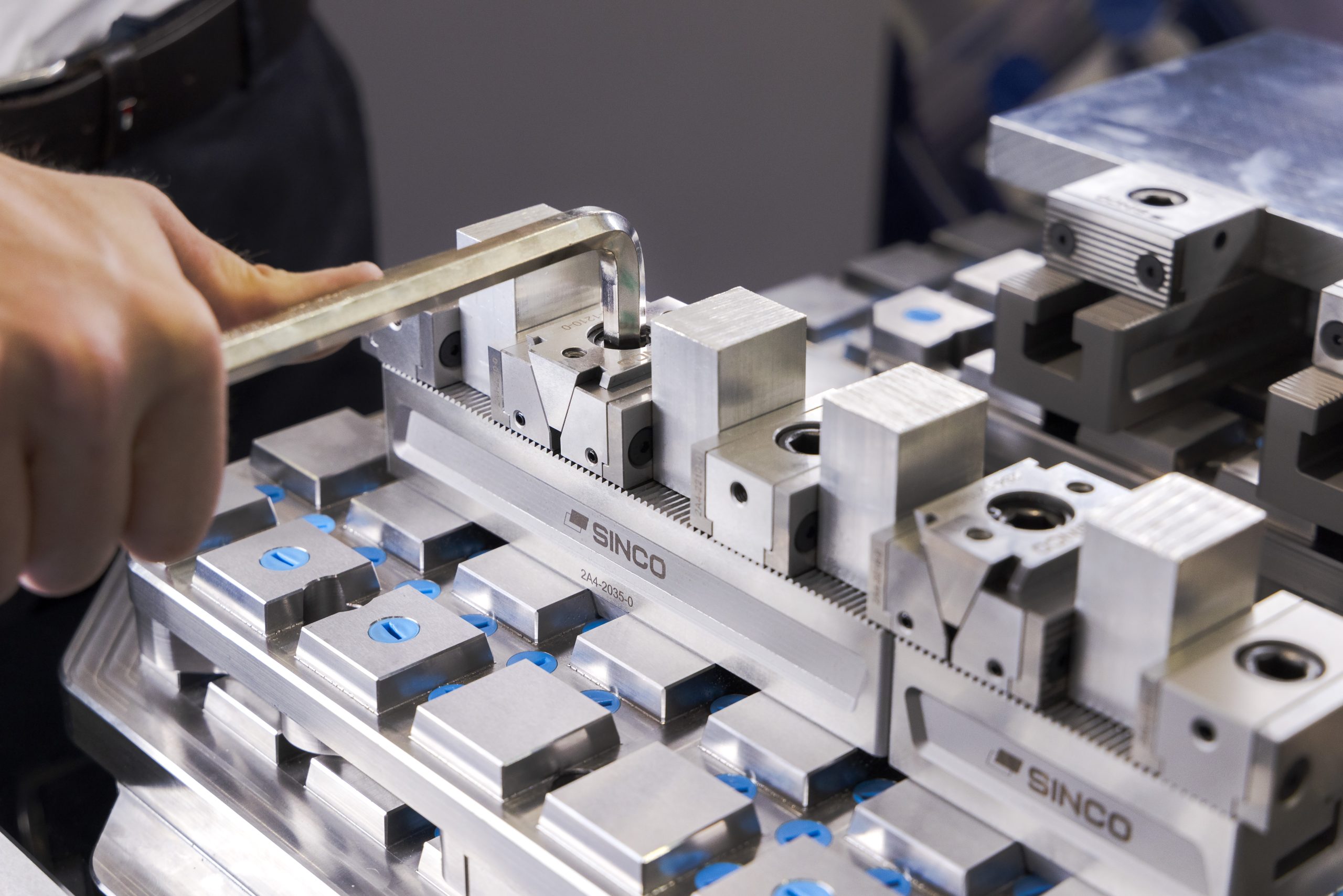

SINCO MULTI-PART CLAMPING REVOLUTIONISES CNC MACHINING EFFICIENCY With hundreds of zero-points across the table or pallet of a vertical or horizontal machining centre, Sinco MultiZero workholding offers ultimate modularity and exceptionally high precision for securing multiple components for machining. The systems are sold into the UK and Irish markets under an exclusive agency agreement […]

Read more