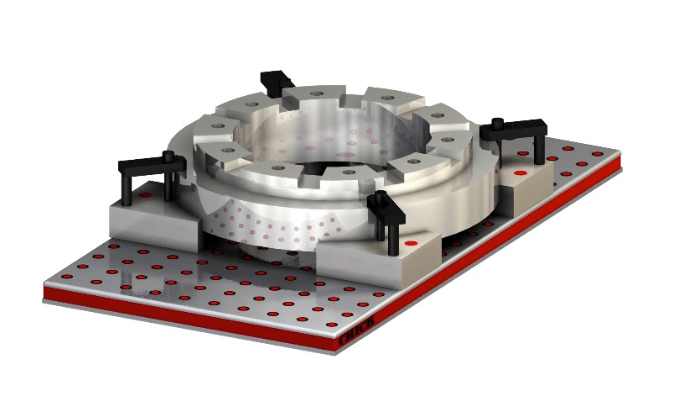

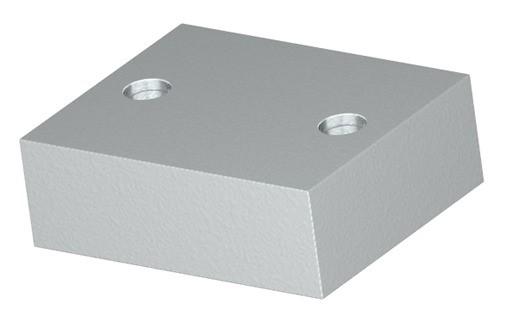

Foundation Plate

Description

Foundation plates are angle irons used to modify irregular foundation surfaces, such as stone or rough concrete. These specific plates are highly beneficial and cost effective in that they eliminate the need to pour new concrete or propose new forms. We offer a range of foundation plates that can be tailored to fit a range of machine specifications, such as the chick work holding foundation plate. To ensure the highest quality and durability foundation plates are made from cast iron, which can serve as a worthwhile investment.

£ Price on application

Further Information

It offers:

- A standard grid pattern to simplify designing, cataloguing and utilisation of fixtures, providing consistency and repeatability to set-ups.

- Length and width tailored to the machine’s work envelope.

- Precision ground cast iron to 35mm thick.

- 50mm spaced holes, drilled and tapped, for use as both location and hold down. Sealed with chip plugs.

- An alpha-numeric labelling system.

- Minimises set up time from workholding system to system.

- Machine interface mounting holes, customised for each machining centre.

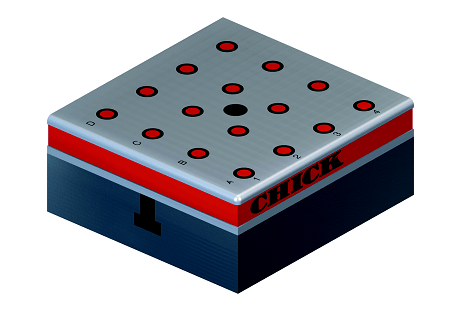

An alpha-numeric labelling system to simplify building and cataloguing of fixtures.

An alpha-numeric labelling system to simplify building and cataloguing of fixtures.

50mm grid pattern of bushed and tapped holes.

50mm grid pattern of bushed and tapped holes.

Each hole within the 50mm grid pattern has a 12mm bushing for accurate location and an M12 thread for bolt down. These holes are sealed with patented chip plugs preventing the build of chips/swarf.

Customized for each machining centre. The hardware necessary to mount the Foundation to the machine table is included

Customized for each machining centre. The hardware necessary to mount the Foundation to the machine table is included

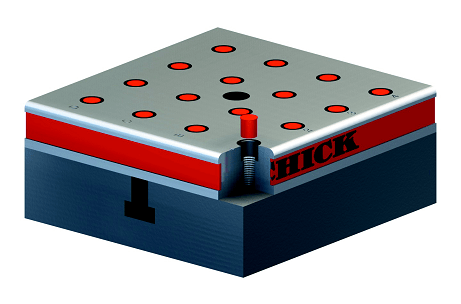

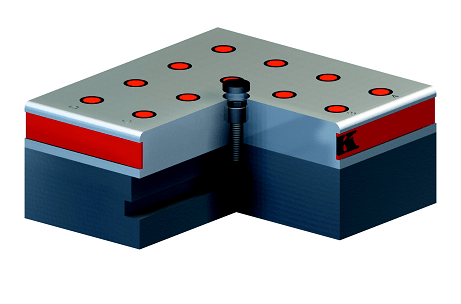

Accuracy and repeatability are further enhanced through the use of purpose designed M12 bolts with precision ground shoulders and dedicated Chick Foundation Blox – high strength aluminium blocks that can be machined into a dedicated component for individual set ups.

050-0001 – Foundation Blox

Foundation Blox are blank, high strength aluminium blocks that are machined into a dedicated component of the set-up. Ideal for designing component modular fixtures on Foundation Plates

050-0002 – Accurate Bolts

050-0002 – Accurate Bolts

M12 bolts with a ground shoulder that provides precision repeatability when using Foundation Blox or any other modular fixturing components.