Get a Grip: Why Expanding Mandrels from 1st MTA Are the Smart Choice for Internal Workholding

When it comes to workholding, external clamping gets most of the attention — but internal gripping is often the real challenge. Whether you’re working with thin-walled parts, precision bores, or long, awkward components, choosing the right mandrel can make or break your machining accuracy. That’s where expanding mandrels from 1st MTA come in.

We don’t just supply workholding — we engineer it. From standard solutions to fully custom designs, our expanding mandrels are built to deliver accuracy, repeatability, and reliability where it matters most.

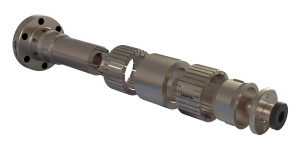

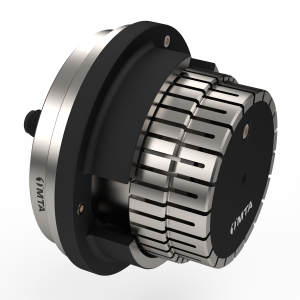

What Is an Expanding Mandrel?

Expanding mandrels are internal clamping devices used to hold components securely from the inside. As the sleeve expands, it grips the bore of the part with uniform pressure — making it ideal for applications where external clamping isn’t possible or could cause distortion.

At 1st MTA, our expanding mandrels are suitable for:

They offer a safe, precise, and efficient method of internal workholding — especially for delicate or high-value parts.

Buying a mandrel isn’t just about dimensions — it’s about performance. That’s why engineers and manufacturers across the UK choose 1st MTA as their trusted partner.

Here’s what sets our mandrels apart:

Precision You Can Rely On

Versatility Built In

Custom Solutions? Absolutely.

Let’s face it — not every component plays by the rules. When your part has a non-standard bore, tricky length-to-diameter ratio, or simply doesn’t work with off-the-shelf options, our custom expanding mandrels are the answer.

Whether you need:

Our technical team will work with you to design a mandrel that fits your exact requirements — no compromises, no shortcuts.

Why Trust 1st MTA?

At 1st MTA, we’ve been helping engineers solve workholding challenges for decades. We don’t believe in one-size-fits-all — we  believe in listening, understanding your process, and delivering the right solution, first time.

believe in listening, understanding your process, and delivering the right solution, first time.

When you work with us, you get:

We don’t just help you get a grip — we help you keep it.

Have a part that’s proving tricky to clamp internally? Whether you’re working with precision components or production volumes,

1st MTA has the experience, products, and technical knowledge to help.

? Call our team

? Send us your drawings

?️ Let’s engineer the right solution — together