Workholding and automation equipment specialist 1st Machine Tool Accessories (www.1mta.com) is able to supply two ranges of products that offer high accuracy workholding for EDM applications workpiece positioning accuracy as well as secure retention when immersed in a fluid. They are therefore ideal for wire-cut and die-sink electro-discharge machining (EDM) of components in a tank containing a deionised water or oil dielectric.

Both methods of spark erosion present challenges. The accuracy of the finished part is directly linked to the precision with which the workpiece is positioned, while maintaining a rigid setup is crucial to preventing vibration and ensuring a consistent spark gap. The workholding equipment has to be able to be submerged and resist corrosion, and if it includes automated functionality, must integrate seamlessly with the EDM machine control to ensure an efficient workflow.

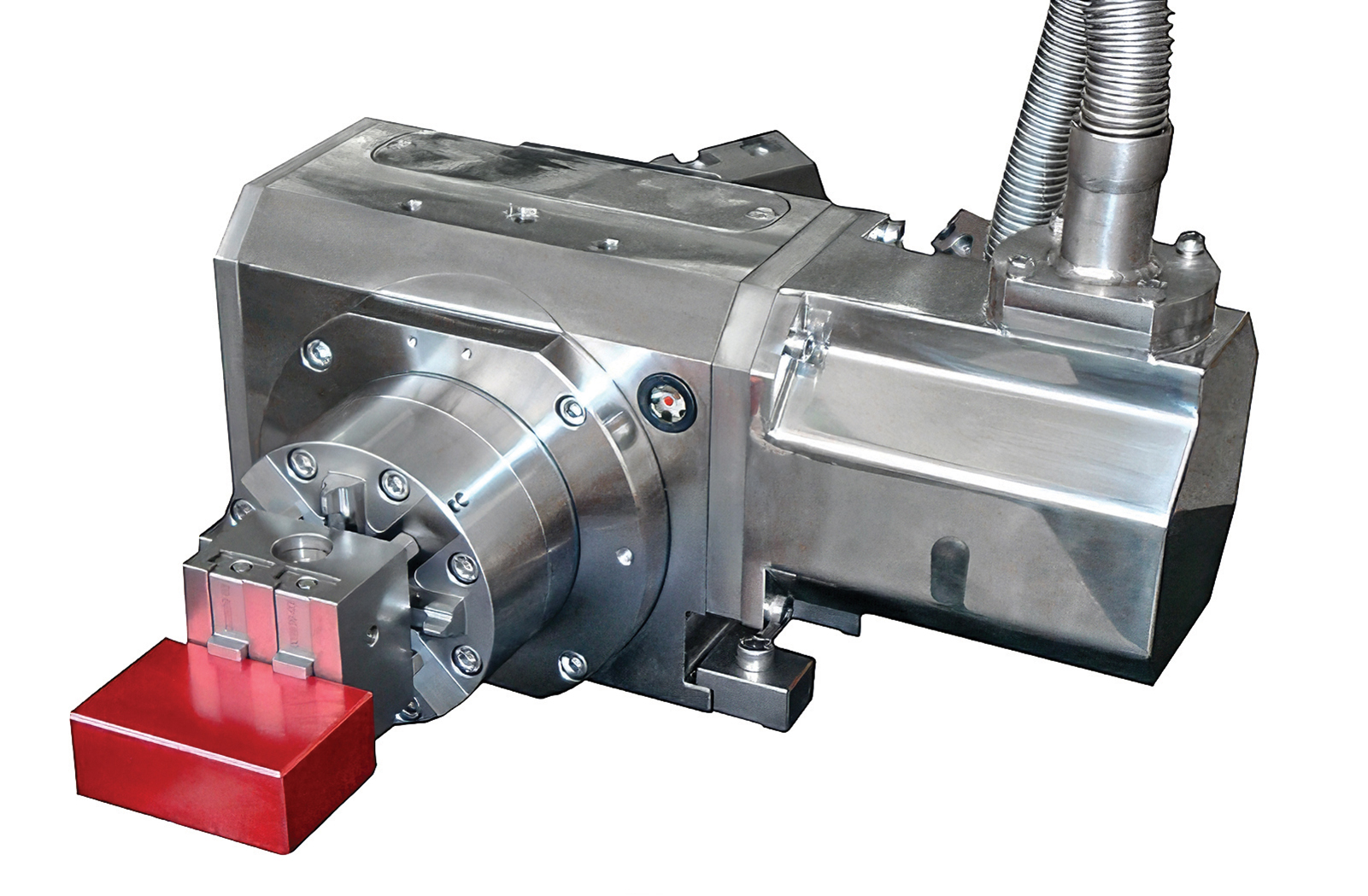

Kitagawa rotary tables

Kitagawa’s DM100 and DME100 precision rotary tables are engineered to address the rigorous demands of these machining conditions. Fluid-proof and rust-proof, they are manufactured using materials and sealing mechanisms that confer an IP68 rating and allow for submersion to half a metre. Constructed from stainless steel, the tables have outstanding rigidity as well as corrosion resistance.

At the heart of their accuracy is a precision-ground worm gear that minimises backlash and ensures accurate indexing and rotational movement, critical for achieving tight tolerances and smooth surface finishes. They also feature robust pneumatic or hydraulic clamping mechanisms that provide substantial holding force, preventing workpiece movement during the EDM process and ensuring optimal stability.

The Kitagawa DM100 offers precise, automated indexing using the manufacturer’s independent Quinte controller. It facilitates automated, multi-axis machining, enabling complex 3D contours and helical features on the workpiece to be achieved by synchronising the rotary table’s movement with the machine’s linear axis motions. The DME100 rotary table is designed to be operated directly from the EDM machine’s control system, rather than a Quinte controller. Both configurations are of robust design, ensuring consistent accuracy, while their compact size and relatively lightness make them easy to integrate into spark erosion machines, which often have limited working envelopes.

The automation provided by both units significantly shortens cycle times and eliminates the potential for human error in positioning, leading to excellent repeatability and superior part-to-part consistency. Complex indexing patterns are pre-programmed, streamlining job changeovers. As the demands on EDM technology continue to grow, the uptake of these rotary tables in machine shops is set to increase due to their ability to deliver high levels of precision, productivity and profitability.

The exceptional precision inherent in EDM, which is capable of achieving sub-micron machined tolerances, is fundamentally contingent upon the workpiece being held with an equivalent degree of accuracy and stability. The Sinco MultiZero modular zero-point clamping solution does exactly this, while it also represents a significant advance in efficiency, accuracy and flexibility of workholding. Setup times are shortened and variability in machining is reduced by establishing a standardised, repeatable platform for workpiece retention.

In die-sink applications, the system allows the seamless transfer of workpieces from preceding machining processes such as milling, while meticulously preserving the initial zero-point datum. In wire EDM, workpiece transfer involves a MultiZero adapter plate on top of a pallet. The adapter plate with the clamped workpiece can be removed for wire EDM processing and subsequently repositioned precisely on the pallet. It means that similar accuracy is maintained if the part goes for subsequent milling or grinding, for example, or inspection on a coordinate measuring machine, provided that those machines are MultiZero-equipped.

Adoption of the Sinco system yields substantial benefits. Maintaining a repeatable precision of 5 microns, it guarantees superior and consistent accuracy. Dramatic reductions in setup times of up to 80 percent are reported and fixture exchange times are lowered to under two minutes. This level of efficiency translates into major productivity gains, exemplified by reported floor-to-floor time decreases of 30 to 40 percent when processing moulds in an EDM machine and 70 to 80 percent when milling electrodes on a machining centre.

The MultiZero base plate serves as the foundational workholding element. It features an array of conical slots typically arranged on a 50 mm pitch, each of which represents a zero point. MultiZero interchangeable pallets equipped with conical centring elements attach to the base plate and can hold workpieces directly, or other accessories such as modular vices may be mounted on top of the pallet to position and orientate workpieces of different sizes and shapes.

The MultiZero P20 mould steel EDM pallet is a special variant designed for spark erosion applications and the simultaneous machining of multiple electrodes. Its surface emulates the Meusburger electrode reference system or it can be adapted to other industry standards. It is notable that the development of the entire suite of MultiZero elements for milling, drilling, grinding and measuring was developed originally with thermal expansion compensation for submerged spark erosion applications.

? enquiries@1mta.com

? www.1mta.com