Workholding as the Hidden Lever in UK Manufacturing Performance

1st MTA White Paper

23 January 2026

Workholding is the foundational enabler of productivity, quality and safety in CNC machining. In the UK manufacturing sector—facing skills shortages, rising cost pressures and automation imperatives—robust workholding systems and strategic partnerships matter more than ever.

This paper explores:

– Why correct workholding is essential for CNC performance in the UK context

– The strategic value of selecting the right workholding partner

– How 1st MTA delivers this value through expert support and broad product offering

– UK‑market data, call‑out insights and actionable recommendations

By placing workholding at the heart of the machining process, UK manufacturers can reduce downtime, boost spindle utilisation, enable automation and retain competitiveness in a global market.

Workholding is not simply a peripheral concern—it underpins every aspect of machine tool performance.

A rigid, secure fixture prevents workpiece motion, vibration or deformation under the cutting forces of modern CNC machines. Movement as small as a few microns can cause: surface defects, scrapped parts and costly re‑setups.

“Even a 0.05 mm shift in part position can render a high‑value aerospace component unusable.”

– Faster Machining: Stable workholding allows higher feed/rate, faster spindle speed, reducing cycle time.

– Reduced Setup Time: Quick‑change vices, zero‑point pallets, standardised fixtures minimise changeover time.

– Automation Compatibility: Modern workholding systems enable “lights‑out” operation—essential in the UK where labour and energy costs are rising.

Correct workholding ensures identical positioning and orientation across setups, reducing variability and meeting tight tolerances.

Vibration and chatter shorten tool life dramatically. Secure workholding smooths cutting loads, minimises tool wear and lowers tooling cost per part.

An unsecured part is a serious hazard. High‑speed machining with a dislodged workpiece can result in damage to machine tools, cost of repair, downtime—and potential injury.

Fixtures that allow multi‑side access (e.g., tombstones, indexers) let manufacturers machine complex parts in one setup, reducing manual handling and secondary operations.

Choosing a workholding partner affects much more than a fixture—it touches precision, throughput, cost control, safety and future automation readiness.

2.1 Enhanced Precision & Quality

Rigid workholding—designed and specified correctly—reduces scrap, improves yield, boosts first‑pass success.

2.2 Increased Productivity & Efficiency

Modular systems and quick‑change fixtures mean less non‑cutting time, more spindle “cut” time, and higher machine utilisation.

2.3 Access to Expertise & Innovation

A partner brings: application engineering, fixture design, integration advice (multi‑axis, automation), and access to latest technologies (sensor‑equipped clamps, zero‑point pallets).

“Access to specialist fixture engineering often saves months of trial and error and pays back via higher throughput.”

2.4 Cost‑Effectiveness

While upfront cost may be higher for advanced workholding systems, long‑term benefits (less scrap, more uptime, longer tool life) deliver ROI.

2.5 Improved Safety

Robust, proven workholding systems reduce risk of accidents and machine downtime—critical in high‑cost UK manufacturing.

2.6 Reliability & Support

Partner reliability in delivery, aftermarket support, and adaptability to changing production volumes or part families is vital.

Why 1st MTA stands apart

Quality Assurance:

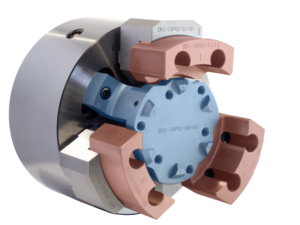

Suppliers such as Kitagawa, Breuning IRCO, Chick and Walmag ensure top‑tier performance and reliability.

Expert Technical Support:

On‑site visits, machine audits, fixture demonstrations and aftermarket support help optimise your setup.

Customised Solutions:

Standard modular fixtures as well as bespoke designs tailored to unique parts, volumes or automation requirements.

Wide Product Range:

High‑density vices, zero‑point pallet systems, magnetic workholding, automated loading/unloading systems.

Focus on Education:

Free workholding seminars for colleges and training centres reflect commitment to up‑skilling UK manufacturing workforce.

– Automation Ready Workholding: Unattended operation, robotics integration and pallet systems.

– Workholding Portfolio: Vices, chucks, fixtures, tombstones, zero‑point and multi‑part solutions.

– Accessories & Multi‑Axis Applications: Magnetic systems, tooling columns, adapted fixtures for 4-/5-axis centres.

A UK precision engineering firm implemented a 1st MTA quick‑change fixture system on their 5‑axis machining centre. Results: 20% cycle time reduction, 30% scrap reduction and seamless future robotics integration.

Actionable Best‑Practices

– Analyse “stick‑time”: ratio of cutting vs idle spindle time. Workholding that reduces changeover improves this ratio.

– Standardise fixtures: by using repeatable fixture interfaces (zero‑point, pallet systems) to minimise machine downtime.

– Design for automation: choose workholding that is robot/pallet compatible from the start.

– Select the right workholding for volume and complexity: multi-part fixturing for high volume; flexible modular systems for mixed-product shops.

– Ensure set-up stability: check for vibration, deflection, clamping force.

– Monitor ROI: track KPIs: setup time, scrap rate, tool-life, machine utilisation.

– With automation market growth and UK productivity improvement outpacing many peers, manufacturers must treat workholding as a strategic lever, not just an additional cost.

– Address the skill gap: with only a portion of UK manufacturers heavily automated (~23% implementing; ~62% planning) there is a clear need to raise workholding competence. soe.org.uk

– Prioritise fixture systems that support “lights-out” machining to squeeze more value from existing machines as investment remains challenged.

UK Automation Adoption – 23% of UK manufacturers have fully implemented automation; 62% are planning automation investments (SOE.org.uk)

In UK manufacturing, where cost pressures, skills gaps and global competition are ever present, workholding is not optional – it is essential. Correct workholding delivers accuracy, efficiency, safety and throughput improvements.

Key takeaways:

– Evan the best CNC machines will under-perform without appropriate workholding systems. Correct workholding is essential for CNC productivity, quality, safety, and automation readiness.

– A strategic partner providing expertise, technology, high-quality systems, automation readiness, support and UK-market knowledge is a competitiveness multiplier.

– 1st MTA offers that partnership, backed by top brands, engineering support and UK-focused solutions with expert guidance.

– Manufacturers leveraging advanced workholding can improve throughput, reduce costs, and unlock “lights‑out” production potential.