With hundreds of zero-points across the table or pallet of a vertical or horizontal machining centre, Sinco MultiZero workholding offers ultimate modularity and exceptionally high precision for securing multiple components for machining. The systems are sold into the UK and Irish markets under an exclusive agency agreement by 1st Machine Tool Accessories, Salisbury, which also provides a consultancy service to manufacturers wishing to maximise the advantages of the Slovenian-made workholding equipment.

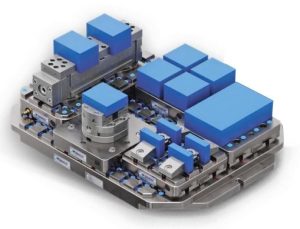

Central to Sinco’s approach to increasing CNC machining efficiency and profitability are the novel, virtually limitless workholding arrangements made possible by its MultiZero base plate. It features across the entire surface an array of precisely spaced, conical, zero-point locations at 50 mm or 100 mm centres. The high density grid maximises machine capacity usage by simplifying multi-part clamping all over the machine table, utilising matching centring elements on the underside of other MultiZero modules that fit accurately into the conical holes.

The additional modules include clamping pallets that attach directly to the base plate and can hold workpieces directly. Five different pallet types are available for manual or automatic clamping of parts on a machining centre, while a die-sink or wire-erosion EDM machine, measuring machine or assembly station may be similarly equipped. Pallets can be supplied fitted with an RFID chip to allow integration into an Industry 4.0 factory environment, enabling automation, digitalisation, automatic data capture and scheduling of production.

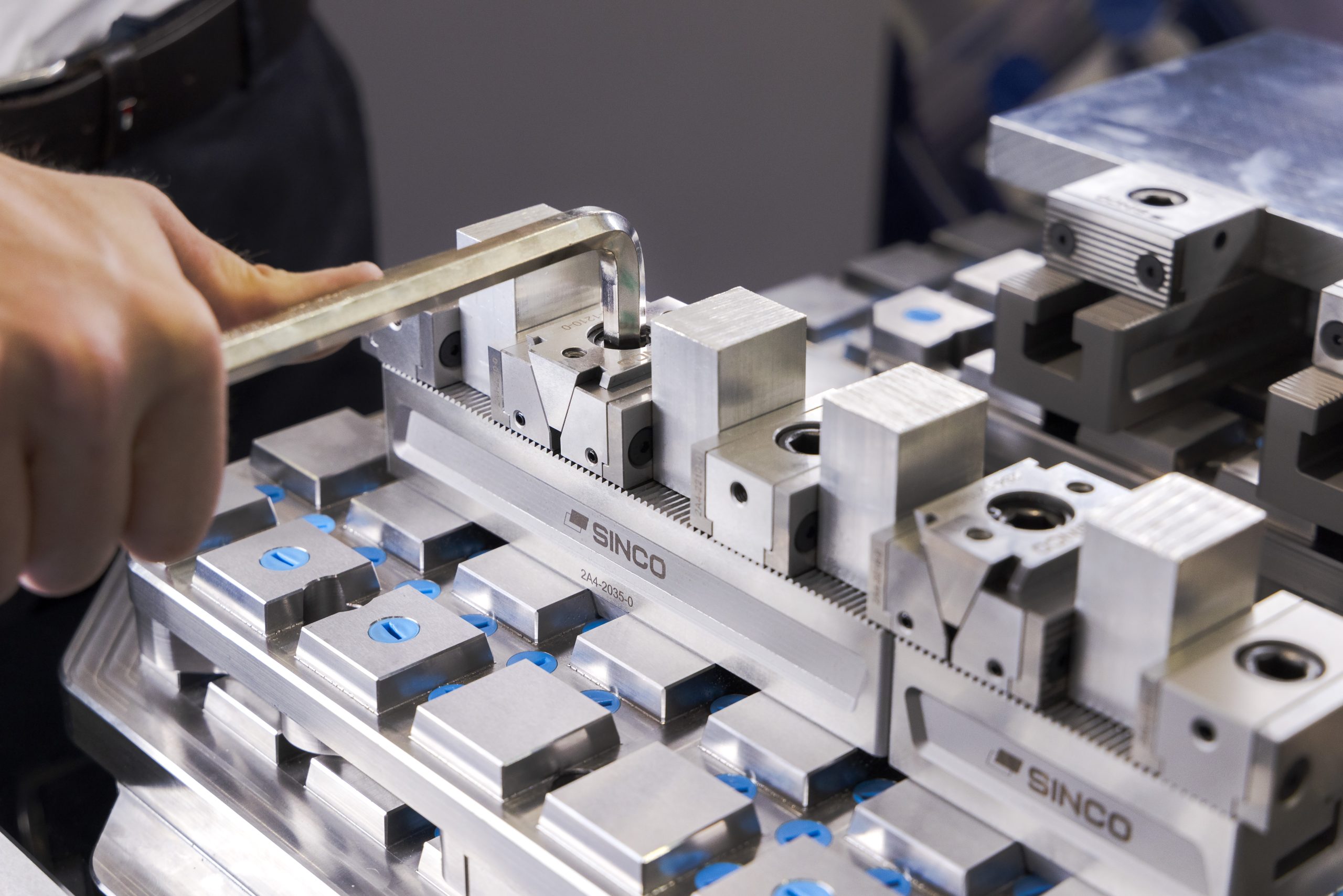

Other accessories such as modular vices, stoppers and risers can be mounted on top of the clamping pallet in countless ways to suit different workpiece sizes and shapes. The absence of unnecessary jaws exposes the maximum surface of the workpiece, reducing the number of set-ups and operations needed for completing the machining or inspection. Sinco claims a repeatability of 5 microns each time a new clamping elements is added to one of their workholding set-ups, allowing very high precision machining.

Each mechanical element is secured with an M12 screw having 65 kN of holding power, while pneumatic modules are rated at 55 kN. Pallets are held to the base plate with a force of 260 kN, making the whole configuration very rigid.

In today’s highly competitive manufacturing environment where every second of machine uptime directly impacts the bottom line, the ability to maximise machine utilisation and reduce costly idle time is paramount. The Sinco MultiZero system directly addresses these challenges by offering a robust, flexible and highly accurate workholding solution that empowers machine shops to achieve unprecedented levels of productivity by clamping multiple parts at the same time.

In this way, a machine can continue cutting for significantly longer without manual intervention from an operator. It not only extends unattended production time but also frees up skilled machinists to manage multiple machines concurrently, or to focus on higher-value tasks such as programming, quality control and strategic planning.

The traditional bottlenecks associated with frequent workpiece changeovers, tool exchanges and machine set-up adjustments are dramatically reduced, leading to a substantial increase in factory throughput and a reduction in the overall cost per machined part. These improvements are magnified if the extended spindle engagement time allows a machine shop to move towards more lights-out manufacturing.

Beyond set-up efficiencies, the Sinco MultiZero system contributes to a reduced number of tool changes, leading to increased productivity. When machining a series of identical workpieces, instead of changing tools multiple times for each individual part, a single tool can perform the same operation across all clamped components before it needs to be returned to the tool magazine, leading to a more streamlined and efficient machining cycle.

While the benefits of multi-part clamping are clear, implementing such a strategy can present challenges, particularly concerning complex programming, accommodating variations in workpiece sizes and the need for highly adaptable fixturing. Sinco MultiZero directly addresses these challenges through its innovative design and the provision of a virtual model for each workholding element. The 3D data can be integrated into the programmer’s CAD/CAM system to allow the pre-planning of workholding strategies, improving the efficiency of the cutting cycle that is generated and preventing potential problems later in the production process.

1st MTA is committed to partnering with manufacturers to integrate a game-changing Sinco production strategy into their workflows, and to provide the support needed to optimise machine utilisation, reduce idle times and achieve higher production output. Shops that embrace the Sinco MultiZero system will not only streamline their processes, but also gain a significant competitive edge by unlocking new levels of efficiency and profitability.