How Automation, AI, and Workholding Innovation Are Reshaping Industry, Skills and Careers in the UK

Executive Summary

With investment in automation in UK factories predicted to grow steeply over the next five years, the real challenge is not the availability of the technology, but its practical adoption. OEMs and subcontractors widely report that a lack of technical skills in the workforce is a barrier to harnessing the power of automation, robotics and artificial intelligence (AI) to achieve higher levels of productivity and profit. This white paper outlines a pragmatic, high-ROI path forward.

The following are examined:

- When a robot is — and isn’t — the right automation solution

- Why specialised automation systems such as advanced workholding or bar‑feeding may offer better value in many scenarios

- Strategies to close the UK engineering & automation skills gap

- The convergence of AI and automation, and the implications for UK manufacturing

- Why engineering and manufacturing remain excellent career choices in the UK, despite technological change

Key findings relating to the UK:

- The UK factory automation & industrial control systems market is forecast to grow strongly, with a compound annual growth rate (CAGR) of over 10% between 2025 and 2030. Mordor Intelligence

- The UK has a manufacturing robot density of ~111 robots per 10,000 employees as of 2023, below many Western peers. automate-uk.com+2FS Studio+2

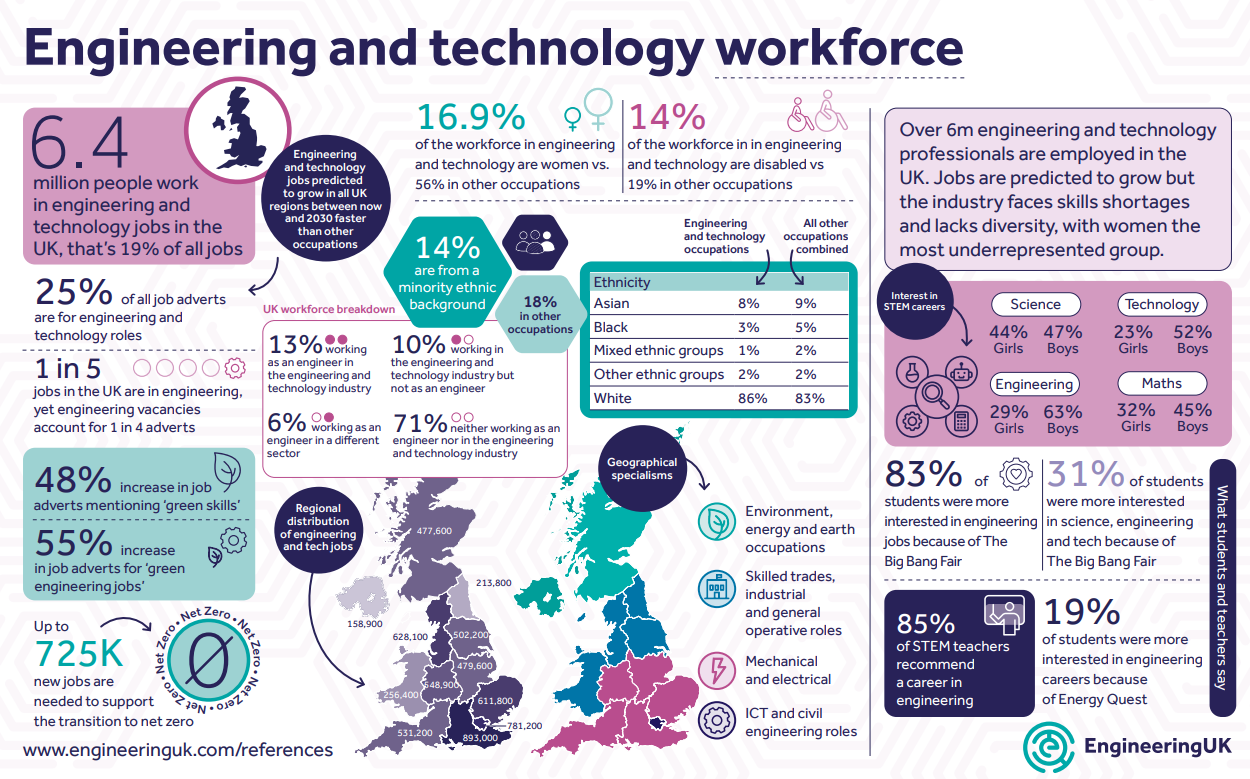

- Engineering & technology roles account for ~19% of UK employment (~6.4 million people) and ~25% of all job‑advertisements. engineeringuk.com+2engineeringuk.com+2

- Nearly half (46 %) of UK manufacturers cite “lack of technical skills” as a major barrier to automation uptake. Make UK

For 1st MTA, this is both a challenge and an opportunity: by providing advanced workholding, flexible automation‑compatible fixturing and modular systems, the company can help UK manufacturing bridge the gap between manual setups and full robotics‑led cells and position itself as a key enabler of “smart manufacturing.”

Robots Are Not Always the Right Automation Solution

The Limitations of Robotic Automation in the UK Context

Robots often represent the “ultimate” automation vision but for many UK manufacturers they may not be the optimal first step. Key limitations include:

- Tasks requiring human judgment and flexibility: Robots excel at repetitive, structured tasks, but struggle with ambiguity, variation or human‑centric roles.

- High cost and ROI risk: Initial investment, programming and integration costs can make robots unaffordable or inefficient for low‑volume or highly variable production.

- Maintenance and expertise overhead: Running and maintaining robots demands specialised skills and ongoing costs, which is a barrier especially for SMEs.

- Limited adaptability to change: Many robot deployments are task‑specific; changes in product mix, fixturing or process often require re‑programming or hardware modifications.

- Simple tasks may be better automated by simpler systems: For work with 1‑2 axes, conveyors, bar feeders or smart fixturing may offer faster payback.

- Human‑interaction roles remain inherently human: In sectors requiring empathy, creativity or interpersonal judgement, robots are not a direct substitute.

Why UK Manufacturing Needs to Think Before Concluding that “Robot = Automation”

In the UK, automation adoption is still lagging. For example:

- Only ~7.4 % of jobs in England were estimated to be at “high risk” of automation in 2017. Office for National Statistics

- A 2024 commentary noted that 20,000 of 27,000 UK manufacturing SMEs (with >10 employees) operate without robots. The MTC

- The UK ranks 24th globally for robot density despite the growth trend. The Manufacturer+1

Case Study – Robot Implementation Gone Wrong

A UK automotive component supplier invested in a robot for part‑loading on a low‑volume line. After six months, the system was idle for long periods due to frequent changeovers and programming overhead. It was replaced by a modular bar‑feeder and a smart workholding solution with higher uptime and quicker changeover. (Anonymised for confidentiality.)

1st MTA: offers workholding and automation‑friendly fixturing as a pragmatic stepping‑stone between manual machining and full robotic cells.

Workholding & Automation: The Foundation

High‑Density Workholding and Multi‑Part Fixturing

Improving workholding and placing more parts under the spindle is a key automation strategy:

- Reduces manual loading/unloading and setup time

- Increases unattended operation and “lights‑out” capability

- Enhances repeatability, accuracy and process stability

- Facilitates integration with automation systems (robots, pallet changers, feeders)

In the UK, since robot density remains relatively low, optimising what happens within the machining centre via workholding is often the more immediate productivity lever.

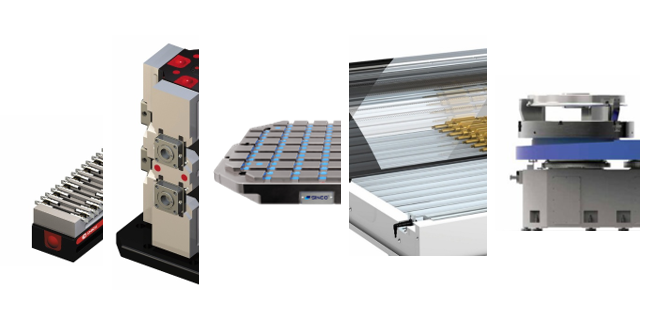

How 1st MTA’s Products Fit with Automation

1st MTA offers a range of automation‑compatible workholding solutions:

- Chick Qwik‑Lok vices — rapid part changeover, multi‑part capability

- Chick Multi‑Loks — high‑density clamping for multiple parts in one setup

- Sinco zero‑point clamping — rapid fixture plate changeover, pre‑loaded away from the machine

- Automated loaders/pallet systems — enabling unattended production

These allow manufacturers to reduce spindle idle time, increase cutting time, and prepare the machine tool environment for higher levels of automation.

UK Market Context for Automation & Workholding

- UK factory automation & industrial controls market projected to grow from £12.3 billion in 2025 to £20.3 billion by 2030, a CAGR of ~10.5 %. Mordor Intelligence

- UK industrial automation & control systems market recorded revenue of £8.89 billion in 2024, expected to reach ~£14.82 billion by 2030. Grand View Research

- Automation benefits in UK manufacturing include increased productivity, better quality and reduced dependency on labour. In-Comm Training Services

Mini Case Study – Multi‑Part Fixturing Implementation

A UK precision engineering firm adopted a high‑density fixture allowing 8 parts per setup (rather than one). Result: setup time reduced by 60 %, unattended machine hours increased by 30 %, component throughput improved by 22 %. The company then reinvested part of the productivity gain into future robotic readiness.

Closing the UK Engineering & Automation Skills Gap

Current UK Skills Landscape

- ~6.4 million people work in engineering & technology roles in the UK (≈19% of all employment). engineeringuk.com+1

- Engineering & technology jobs account for ~25% of all UK job adverts. engineeringuk.com+1

- The UK faces a projected shortfall of up to 1 million engineers by 2030. Society of Operations Engineers

- Nearly half (46 %) of UK manufacturers identify “lack of technical skills” as a barrier to automation. Make UK

- UK manufacturing robot density remains below many peers. The Manufacturer+1

Strategies for Closing the Skills Gap

- Invest in training and reskilling: Upskill current workers in AI, robotics, automation controls.

- Improve the talent pipeline and diversity: Engagement from schools, promoting STEM, attracting women and under‑represented groups.

- Strengthen collaboration: Industry‑academia partnerships, regional skills hubs and employer‑led training.

- Embrace automation strategically: View technology as augmentation not replacement; plan human‑machine roles.

- Focus on foundational skills: Engineering principles, digital literacy and systems thinking remain vital.

Geographic and Sectoral Focus

Different regions in the UK face varied skills gaps. For example, areas with a higher density of advanced manufacturing (West Midlands, North West) require targeted local training programmes.

Case Study – Skills Investment for Automation

A UK manufacturer partnered with a regional college to upskill machine operators in automation programming and pallet‑system management. Over 12 months, the operator downtime reduced by 18 % and the plant could run two additional overnight shifts unattended. The workforce gained new responsibilities, improving staff retention and morale.

AI and Automation — Convergence & Industry Impact

Understanding the Crossover

- Automation: The use of machines and software to execute repetitive or rule‑based tasks with minimal human intervention.

- AI (Artificial Intelligence): Systems capable of learning, decision‑making, pattern recognition, and adaptation.

- Intelligent Automation: Combining automation and AI to handle not only repetitive tasks but also contextual, unpredictable or complex tasks.

UK Manufacturing Impacts

- Increased efficiency & productivity: Automation integrated with AI optimises flow, minimizes waste and boosts output. In-Comm Training Services+1

- Enhanced quality: AI‑driven inspection and automation reduce defects and increase consistency.

- Predictive maintenance: AI analyses sensor data; automation triggers proactive maintenance before failures occur.

- Cost reduction & sustainability: Smart systems reduce energy use, downtime and scrap.

- Workforce transformation: New roles for engineers in AI oversight, system integration and data analytics.

- Industry 4.0 adoption: Smart factories, connected machines, hybrid human‑machine workflows.

Barriers in the UK

- Many UK firms remain hesitant: concerns include cost, skills and integration complexity. The MTC

- UK robot density remains low compared to peers: ~111 robots per 10,000 manufacturing workers in 2023, below the global average (~141). automate-uk.com+2The Manufacturer+2

Case Study – AI + Automation in UK Manufacturing

A UK electronics manufacturer deployed machine‑vision AI to inspect PCBs and linked this to a robotic sorter and pallet‑changer system. Result: defect rate reduced by 45 %, machine idle time decreased by 35 %, and operator supervision time cut by 22 %. The integration required workholding upgrades compatible with automation systems (some supplied by 1st MTA’s customers).

Is Engineering and Manufacturing Still a Good Career Choice?

Why Yes — and Why Now

Transformation, not elimination:

Automation and AI are changing how engineers work — shifting focus from manual operation to oversight, systems integration and innovation.

Strong demand for engineers:

- Growth in high‑value sectors:

Green manufacturing, advanced materials, aerospace/defence, smart factories — these are key growth areas in the UK.

- Lifelong learning is essential:

Engineers must adapt, upskill in robotics, AI, data analytics and sustainable manufacturing — and the pathways exist (apprenticeships, degrees, continuing professional development).

- Great career choice:

Purpose, high employability, global mobility, creativity and innovation remain core benefits of an engineering career.

Pathways for Students & New Entrants

- The engineering and manufacturing industry in the UK is becoming more digital and more creative.

- With tens of thousands of new engineer roles needed per year, this is a high‑opportunity moment.

- Emerging fields: EVs, hydrogen tech, smart manufacturing, bio‑engineering, space technologies.

- Entry routes: university, degree apprenticeships, vocational training — with emphasis on digital skills.

For Current Professionals

- Change = opportunity: New roles in predictive maintenance, AI‑assisted system design, automation oversight.

- Upskilling is key: Focus on robotics programming, IoT, data science, sustainability.

- Foundations still matter: Engineering fundamentals — safety, analysis, problem‑solving — remain central.

- Leadership potential grows: Automation removes repetitive tasks, freeing engineers to lead innovation and optimisation.

Conclusion & Key Highlights

Key Highlights

- UK manufacturing remains vital but must accelerate its automation and AI adoption to stay competitive.

- Robots are powerful, but not always the most practical first step — workholding, load/unloaders and modular systems often provide faster ROI.

- 1st MTA’s portfolio of high‑density workholding, zero‑point systems and automation‑ready fixturing puts them at the heart of this transformation.

- The UK faces a major skills gap — the demand for engineers and automation‑capable staff outstrips supply.

- The convergence of AI and automation is creating new roles and reshaping the workforce — engineering careers are evolving rather than disappearing.

- For students, new entrants and experienced professionals alike: now is a high‑opportunity time to engage with UK engineering and manufacturing.

Final Thoughts

In the next decade, UK manufacturing has the potential to leap‑frog into a high‑productivity era — if it embraces automation, adapts its workforce and links the right technologies with the right processes. Organisations like 1st MTA, which provide the enablers of automated machining (workholding, modular fixturing, automation‑friendly systems), will play a pivotal role in this transformation. For the workforce, engineering remains an outstanding career choice — one defined by innovation, global relevance and the opportunity to shape the future.