At 1st MTA, we are always seeking to bring innovative and reliable workholding technologies to our customers. That’s why we’re proud to partner with Walmag, a leading name in magnetic workholding solutions. With over 25 years of experience and manufacturing expertise based in the Czech Republic, Walmag combines tradition with continuous innovation to deliver outstanding performance, flexibility, and value.

Whether you’re grinding, milling, drilling, or turning, Walmag offers a full portfolio of magnetic systems designed to improve productivity, simplify setups, and ensure maximum safety on the shop floor.

Walmag’s magnetic workholding solutions are backed by decades of research, development, and real-world application. Here’s what makes them stand out:

“We design our magnetic systems to make work simpler, safer, and more efficient. Combine that with long service life and quality support, and you’ll significantly reduce your production costs.”

– Walmag

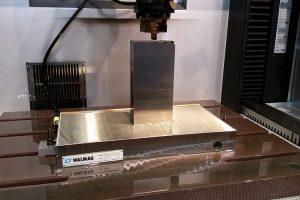

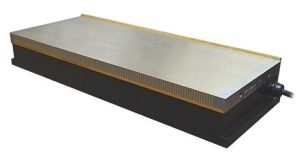

The Mastermill range of electro-permanent magnetic plates offers low-profile, high-performance clamping for milling and drilling of both small and large workpieces.

Ideal for milling, drilling, planing, and heavy grinding, the Neomill Compact delivers holding forces up to 160 N/cm² with excellent stability and coverage.

“Thanks to this solution, we are achieving better production accuracy, and saving time and material. We’ll definitely contact Walmag again.”

– Mr. Konečný, Walter s.r.o.

The Neomicro magnetic plate is a cost-effective, low-maintenance option designed for precise surface grinding and EDM operations.

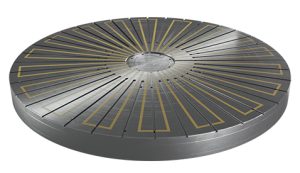

Neostar magnetic chucks are tailored for turning and grinding round or ring-shaped parts, enabling single-setup machining of faces, IDs, and ODs.

The Grindmaster series offers uniform clamping across the entire surface, ideal for grinding a wide range of components with maximum precision and minimal thermal distortion.

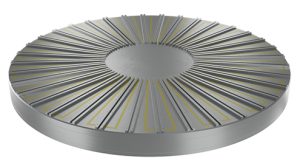

An electro-permanent circular chuck ideal for rotary tables. With radial pole layout, it provides secure clamping without needing continuous power.

Designed for heavy grinding of medium to large parts, the Elmag series features:

The BJP plate is ideal for heavy-duty machining, with clamping forces up to 110 N/cm² and a regrinding limit of 7 mm.

A versatile, competitively priced option for everyday grinding of medium to large workpieces, the Unigrip delivers 90 N/cm² of holding force.

These chucks are designed for precise grinding of very small workpieces.

Perfect for rotary table grinding or turning of parts like bearing rings, bushings, and saw blades.

Walmag also offers:

Customer Confidence: Real-World Success

“We ordered six Walmag permanent magnetic plates 240 × 240 mm adapted to our zero-point system. Walmag’s flexibility and fast delivery allowed us to meet deadlines, and the high quality enabled us to achieve < 0.005 mm tolerances in automated production. Walmag will be our first choice again.”

– Beat Winet, Head of Production, KEBO AG

If you’re looking to improve:

…then Walmag magnetic workholding could be the solution for your shop floor.

? Need Expert Advice?

At 1st MTA, we’re proud to supply Walmag’s extensive product range and help customers implement the right magnetic solution for their specific needs.