In the world of CNC machining, the spotlight is often on precision equipment, advanced automation, and cutting-edge control systems. But when it comes to solving real-world workholding challenges, the technology itself is only part of the equation. The often-overlooked variable — and arguably the most critical — is people.

Workholding may appear to be a purely technical matter, but successfully addressing related issues requires a combination of engineering know-how, mechanical intuition, and strong communication across teams. As many machine shops discover, having the right fixtures, chucks, or collets in place is essential — but not always sufficient — for a stable, efficient, and repeatable process.

Even with top-tier machinery and tooling, unresolved workholding issues can lead to:

These problems typically don’t stem from poor equipment alone, but from misalignments between the workholding system, the part design, the machine, and the machining process. Identifying and addressing these root causes often requires the judgement and insight that only experienced engineers and operators can provide.

A successful workholding solution depends not just on the right product, but also on the people implementing and supporting it. The following personal and technical skills are often the deciding factors:

Understanding the principles of CNC machining, workholding dynamics, and material behaviour is fundamental. This enables better decision-making around fixture selection, clamping force, and part orientation.

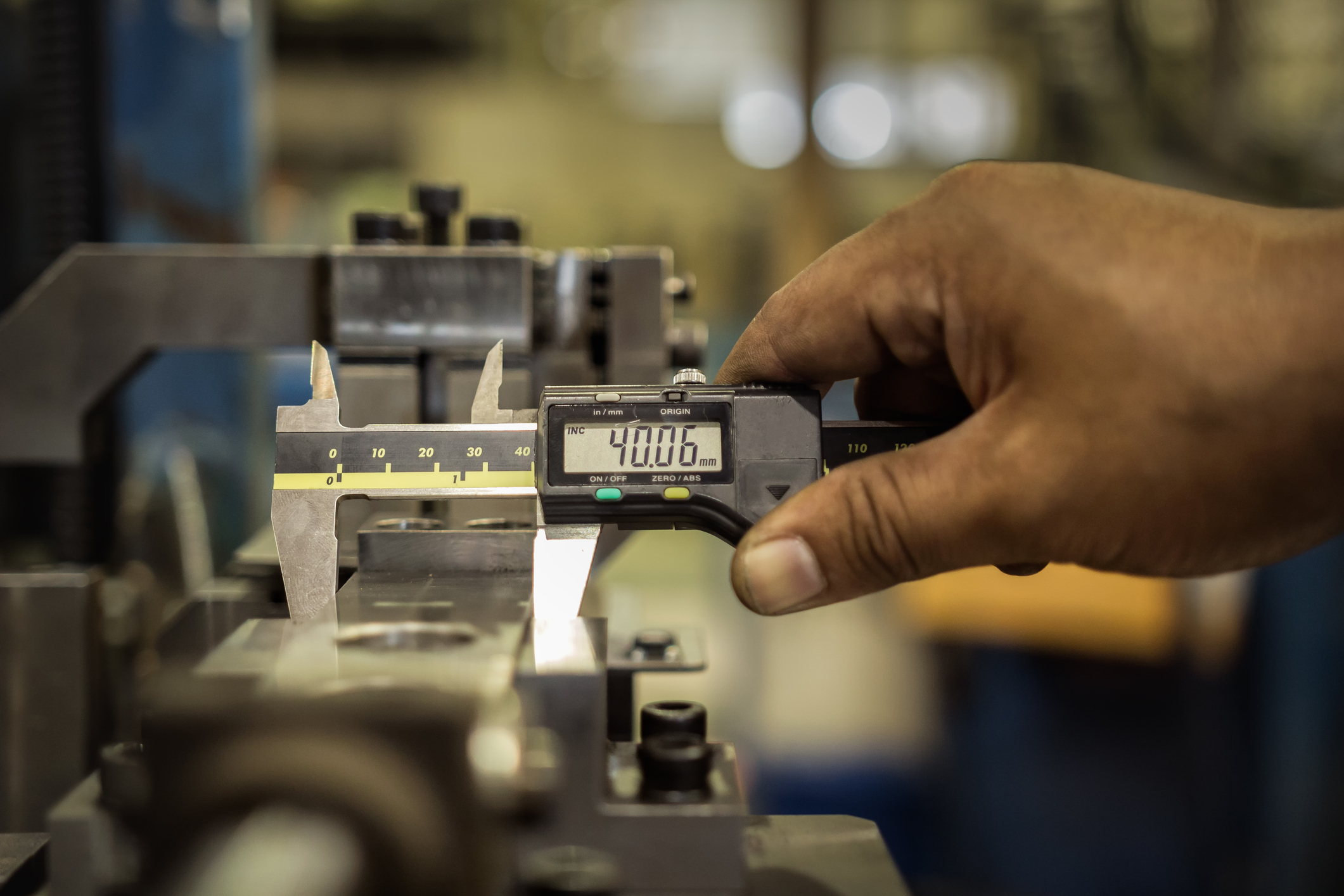

Practical, hands-on experience builds a kind of intuitive awareness — a “feel” for when a setup is secure and when something’s off. This can’t always be taught; it’s honed over time on the shop floor.

Workholding issues are rarely black-and-white. Skilled machinists and engineers must evaluate multiple variables, such as tooling interference, vibration, or thermal distortion, and piece together solutions that are often unique to each application.

Tiny oversights can have major consequences. From jaw wear to misaligned stops, noticing subtle problems can prevent scrap, downtime, and rework.

No two setups are exactly alike. The ability to adapt — whether by modifying a fixture, adjusting torque settings, or implementing a workaround — is crucial in fast-paced production environments.

Complex workholding problems often require collaboration across roles — from machinists and engineers to procurement and external suppliers. Clear, timely communication can accelerate issue resolution and prevent recurrence.

More often than not, solving a persistent clamping or fixturing issue involves multiple stakeholders. Operators may flag early warning signs. Engineers investigate root causes and propose solutions. Vendors or technical support teams contribute specialised knowledge or alternative approaches.

When all these parties communicate well and work together, workholding transforms from a pain point into a performance driver — reducing cycle times, improving part quality, and supporting lights-out machining or automation goals.

While CNC machines and workholding products continue to evolve, the human element remains irreplaceable. Technical skill, mechanical insight, and collaboration are just as critical as any hardware component in ensuring success on the shop floor.

Workholding challenges aren’t just technical puzzles to be solved in isolation — they’re opportunities to engage the full skillset of your team and partners. And that’s often where the real breakthroughs happen.