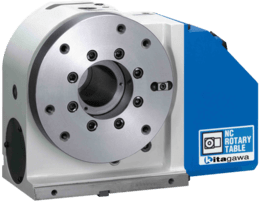

Kitagawa Rotary Tables feature proven technology with high clamping torque, high accuracy, and high rigidity. With a wide range of tables to choose from there is a huge amount of flexibility on offer to meet whatever needs your machine shop may require. A rotary table is a quick, easy, and inexpensive way of increasing the capabilities of your machining centre, allowing you to increase accuracy, decrease cycle times, and machine more complex parts.

A Kitagawa Rotary Table can add extra rotary axes to your current machining setup, effectively turning your three-axis machine into a four-axis or five-axis machine, for a fraction of the cost of a new machine with comparable specifications. Your three-axis machine can have far improved precision and performance, therefore raising versatility of production, reducing the number of seperate machining operations, and increasing the complexity of parts that can be produced.

Every time a workpiece is repositioned between operations, there is a loss of accuracy as it isn’t possible to place the workpiece in exactly the same place every time. Every extra operation makes it harder and harder to meet the strict machining tolerances that are often demanded in today’s environment. With a rotary table, you can machine multiple part sides in a single setup, ensuring high accuracy and tolerances throughout the entire machining process.

The range of Kitagawa Rotary Tables on offer is wide, with standard tables complemented by more specialist ones, giving utmost flexibility in fulfilling whatever machining needs are required.

As well as the industry standard MR series, rotary tables are available with motor casings on any side including behind and on-top to make the best use of your machining envelope. The CK series is the world’s thinnest rotary table for when space inside your machining centre is limited, and both 4th and 5 axis tables have multi-spindle options for machining multiple parts at the same time.

The TP Series has a very large thru-hole for machining very large workpieces such as oil pipes, the DM series is for use underwater in EDM machining, and the LR series has been uniquely designed for horizontal machining with its high durability.

If you would like more information on any of the Kitagawa Rotary Tables, contact us on 01725 512517 or enquiries@1mta.com to speak to one of our technical engineers or arrange a FREE on-site visit from one of our technical representatives. We look forward to hearing from you.

| Book a FREE onsite visit |