Following on from our previous previews of 1st MTA’s presence at the 2016 Mach Exhibition, here you can see a sampling of the collet chucks, custom chuck jaws, and steady rests that will be on show. If you would like to see our previous Mach 2016 previews, please follow the links below.

Mach 2016 Preview – Tecnomagnete

Mach 2016 Preview – Chick Workholding and Kitagawa NC Rotary Tables

EXTENDED RANGE OF COLLET CHUCKS

An extended range of collet chucks from Kitagawa will be exhibited, including standard short and long chucks and quick-change variants. Pull-back types, designated DHP, provide secure and accurate clamping of components and generate a powerful holding action for first-operation work. Other models like the fixed-length DHF range feature a removable bore stop, fixed collet position and high accuracy to ensure precise second-operation machining.

All chuck mounts suit a wide range machine tool types and have been designed to be both compatible and quickly interchangeable with other quick change collet clamping heads, without the need for special adaptors. The lightweight units are a good choice if a lathe spindle has a low maximum allowable weight based on its bearing load capacity and collet chucks are also popular for applications involving high spindle speeds.

Moreover, such chucks apply clamping force all around the circumference of a part instead of at a few contact areas, leading to tight concentricity. This can be particularly significant for second-operation work where accuracy relative to the first operation is needed to avoid tolerance build-up. Collets also open and close faster and can be exchanged more quickly than jaws, boosting productivity for both long and short runs.

BESPOKE AND STANDARD JAW CHUCKS

A recent example of 1st MTA’s bespoke, problem-solving approach to workholding involved clamping an irregularly shaped automotive pump housing, in this case using a jaw chuck. The component has two through-holes in a flange that are specified to extremely close tolerances in relation to the central bore. In addition, the taper of the cast body called for a chuck capable of providing substantial pull back characteristics.

Following a detailed evaluation, 1st MTA recommended a purpose-designed back stop and two jaws with a custom profile mounted in a Kitagawa PWT power wing chuck with draw-down action. The solution was subsequently confirmed through a series of tests and the component is now in volume production at a leading component supplier to the motor industry.

A wide range of Kitagawa’s standard chucks will make an appearance at MACH. The NV chuck range has been developed to meet the demand for large power chucks in vertical lathes. Produced in eight models for components from 62 to 1,000 mm diameter, NV series units feature a protective jaw cover and scraper system that prevents the ingress of swarf or coolant into the chuck mechanism. They are rated for maximum speeds up to 2,900 rpm and are designed for use with standard range Kitagawa jaws and Y2035R type cylinders.

Kitagawa’s QJR08, QJR10 and QJR12 quick change chucks are interchangeable with the company’s popular large through-hole B208 / B210 / B212 and BB208 / BB210 / BB212 models. The new units’ base jaws, which are rapidly and simply changed using a manually operated wrench, feature metric serrations to accommodate a wide variety of popular jaw types.

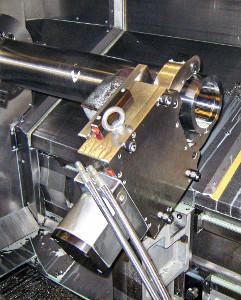

STEADY RESTS

Kitagawa steady rests will be in evidence for shaft machining on lathes and grinding machines. The extensive range boasts a high level of build quality to ensure accuracy and safety on the shop floor. Different versions encompass fixed or travelling positioning, vertical loading, crank shaft turning, models with an actuating cylinder, compact designs for restricted work areas and heavy duty models for components weighing up to 40 tonnes.

1st Machine Tool Accessories will be exhibiting during the Mach Exhibition at Hall 5 Stand 5120 where you will be able to see the range of collet chucks, chucks jaws, and steady rests we have to offer.

If you would like any further information about these or any other products we have to offer, please don’t hesitate to contact us on 01725 512 517 or enquiries@1mta.com.