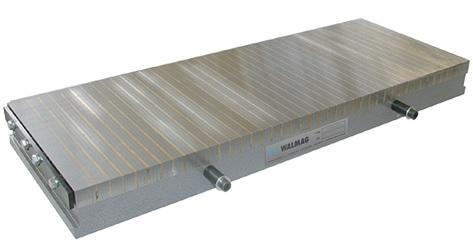

What do you prioritise when it comes to machine workholding? Clamping speed? Holding power? Price? Low vibration? Availability? Ease of comprehension and use? Simple servicing and maintenance? For many, traditional manual clamps are a cost-effective and entirely suitable solution for their workholding needs. They’re cheap, mostly effective and simple to understand. But, have […]

Read more

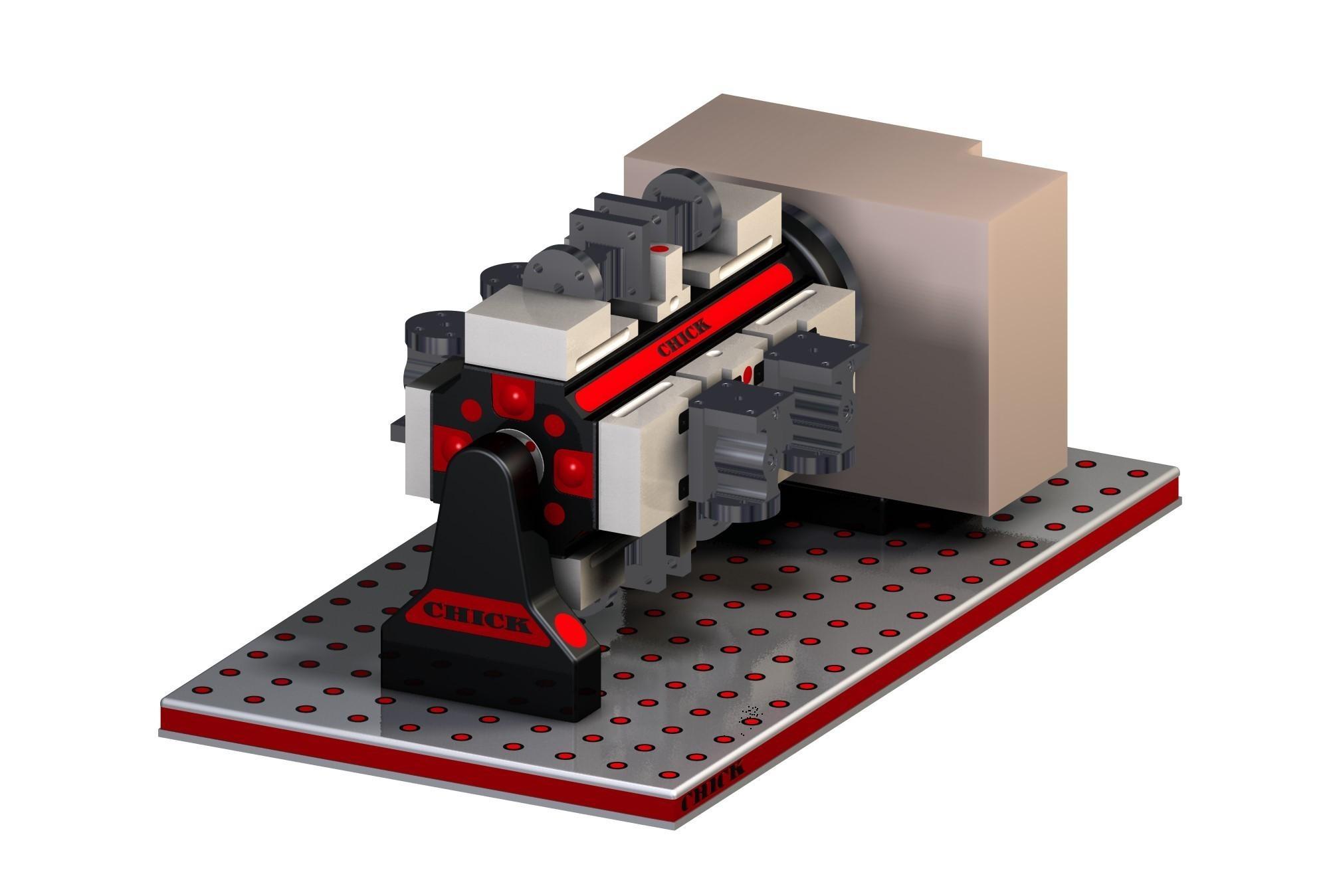

Do you look for workholding solutions that work harder and faster with less effort? Does reducing downtime and maximising productivity remain at the forefront of your priorities? The Chick System 5 consists of several cutting-edge workholding features, each designed to provide the most versatile and efficient workholding solution possible. Whether you’re using workholding personally […]

Read more

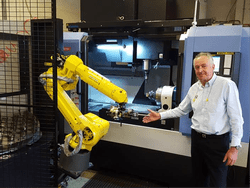

So, who are FB Chain? FB Chain specialise in supplying leaf chain and leaf chain anchor bolts for material handling equipment such as forklift trucks. They supply ready-to-install leaf chain kits to customers across the globe, including Italy and the US. Their goals: Prior to their relationship with HALTER and 1st MTA, the company had […]

Read more

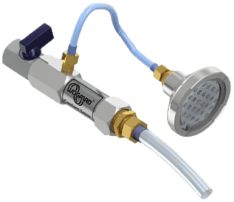

Sustainability is coming to the forefront for all of us in business and our personal lives. Many important decisions going forward will have an impact on our environment, economy and society. Wogaard’s product focus and design team has a clear vision to encompass all the elements and provide oil and coolant solutions that optimise manufacturing […]

Read more

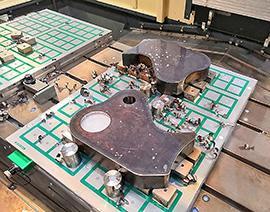

HALTER CNC’s robotic machine tool tending systems are now available in the UK through Salisbury-based 1st Machine Tool Accessories, manufactured in Holland. They expand 1st MTA’s product range to include equipment for automating chucking lathes and machining centres. 1st MTA is the long-time sole agent in the UK for the sale of Italian-built […]

Read more

What are Rotary Tables? Used in CNC machining and metalwork, rotary tables, also known as indexing tables, provide fine control of a workpiece in order to cut work at specific intervals around a fixed axis. Simply put, it needs to control and rotate the workpiece that is being machined. Since precision and accuracy are so […]

Read more

One of the repercussions of Covid-19 has been a widespread discussion about bringing more manufacturing back to the UK, and rightly so in the view of workholding and automation specialist 1st Machine Tool Accessories. But is reshoring large amounts of production realistic in the short term, or is industry unprepared to cope with the higher […]

Read more

As industry in the UK and Ireland emerges from the pandemic lockdown, improvements in production efficiency will be essential to maintain competitiveness in a global marketplace. Many original equipment manufacturers and the subcontractors in their supply chains will be pitching for sales in an environment characterised by fewer business opportunities in the short term, suppliers […]

Read more

In 2019 the Japanese manufacturer Kitagawa introduced the first in a new range of compact, general purpose rotary tables, the MK-series (www.1mta.com/product/mk-series/), for adding a rigid fourth CNC axis to a 3-axis vertical machining centre. One year later the MK200 has been joined by a second model, the MK250, with significantly uprated performance. Availability in […]

Read more

Designed to reduce set-up times on lathes, the new BR-series of 3-jaw chucks from Japanese firm Kitagawa are capable of a gripping accuracy of 0.01 mm TIR (total indicator reading) or less when using optional T-Nuts Plus jaws. Repeatability of jaw exchange is within the same tolerance, even on the largest chuck. They are manufactured […]

Read more